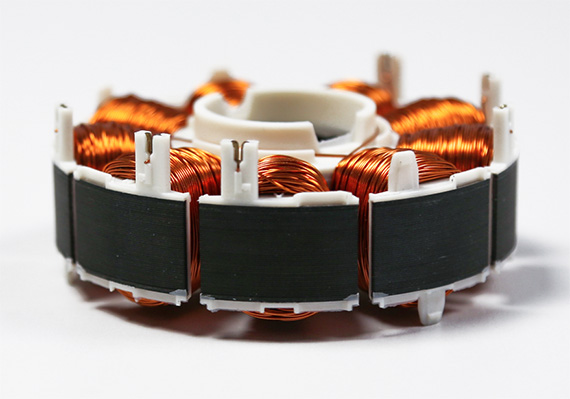

With machines from the “IDC-Line” series, insulation displacement connections can be automated with the highest precision. In the IDC process, insulated wires are directly contacted with connectors without prior stripping. At Schäfer, we offer solutions that implement such connections precisely and reliably using this technology, for example, on the stator of electric motors.

To create the IDC connection, the insulated wires, in this case, a coated wire, are pressed into specially shaped slots of the IDC contact. Sharp-edged blades inside the slots cut through the wire insulation during pressing and establish the electrical contact.

This technology enables a reliable connection without the use of additional elements. The process is fast, simple, and particularly suitable for series production, as multi-core cables can also be contacted simultaneously.

This machine connects the wires of the windings with the respective anchor, ensuring a stable and durable stator that meets the high demands of electric motors.

The integrated sensors for monitoring the insertion depth during each pressing reliably report deviations from the reference. This prevents the use of defective parts in the further process and supports quality assurance.

The safety of the operator during processing of the crimping machine is ensured by a monitored safety device. Opening safety doors interrupts the electrical safety circuit, stopping all motors. The machine fully complies with European directives, both in terms of mechanical and electrical safety and electromagnetic compatibility.

Illustrations of the product are exemplary and may show options as well as specific equipment.

Making further connections

With the IDC station, insulation displacement connections can be automated with the highest precision on machines and systems. In the IDC process, insulated wires are directly contacted with connectors without prior stripping.