Modular Platform

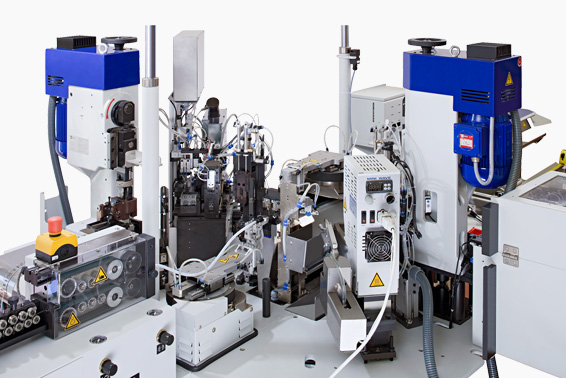

With the SpeedLine crimping machines, Schäfer offers innovative swivel arm wire processing machines for high productivity and diverse applications. The modular platform was developed for different machine variants to provide maximum flexibility for customer-specific requirements. Minimal machine downtime, ergonomic working heights, and the safety concept were the main focus.

Custom Configuration

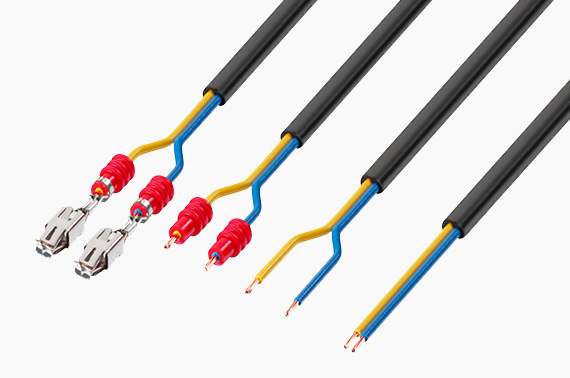

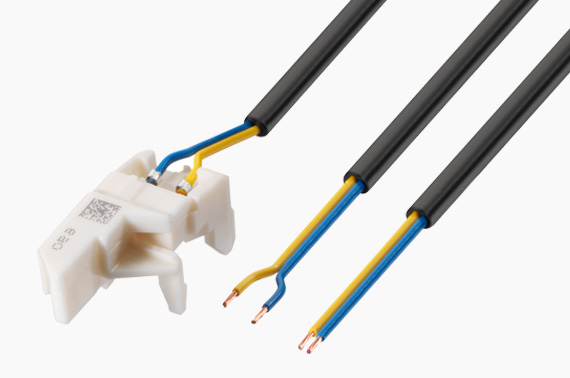

The machine variants are divided into standard models for typical applications and custom configurations for complex solutions. This crimping machine falls into the custom models category and serves individual cable productions with up to 6 stations.

A variety of options allows for different machine configurations to achieve reproducible and complex wire processing. The integration of individual stations, the expansion with additional machine units into a production line, or the implementation of further software functions are possible.

Production in Highest Quality

To ensure product quality, Schäfer offers optional extensions. The crimp force monitoring module reliably evaluates the quality of crimp connections. The conductor quality monitoring reports defective parts due to faulty stripping, and the optical cable quality monitoring inspects the produced cables.

Intuitive and Safe Operating Concept

The WireStar HMI software supports optimum process sequences through its user-friendly operator interface and constant data availability from previous productions. Interaction via the modern user interface is done via a touchscreen and offers a safe handling of the machine.

WireStar‘s excellent networkability contributes to central process coordination and supports through extensive and configurable database management. The integrated networking with Schäfer Connect facilitates process coordination with the operator‘s planning system for resources (e.g. ERP). The dashboard can also be used to display status, production progress and material consumption independent of the installation location.

Conform with the Machinery Directive

The crimping machine for production of high quality connections in terminal and wire processing fully complies with the European directives regarding mechanical and electrical safety as well as electromagnetic compatibility.

Illustrations of the product are exemplary and may show options as well as specific equipment.

Brochure (PDF)

Product description

Base Equipment

- Crimping stations

- Base frame including control cabinet

- Station tables and operating desk

- Wire straightener and swivel arms

- Programmable wire feeder

- Programmable cut and strip module

- Blade assembly and bad part cutter

- Pneumatic machine guard

- PC with touch screen display

- Machine software WireStar

- Networking and interfacing functions

Optional Extensions

- Seal station

- Tinning station

- Double wire straightener

- Crimp height adjustment

- Press height adjustment

- Wire stacking module

- Wire doubler

- Wire spreader

- Wire twister

- Round cable straightener

- Carrier strip chopper

- Applicator shuttle

- Crimp force monitoring

- Cable quality monitoring

- Conductor quality monitoring

- Plug Feeder

Technical Data

Processable materials |

|

| Wire | Single and multi-core wires [1] |

| Cross section: 0.08 mm² – 8 mm² [1] | |

| Insulation: Teflon, PVC, etc. | |

Processing |

|

| Wire feeding | Belt drive with up to 10 m/s |

| Cut length | 30 mm – 99 m [1] |

| Production rate | > 5.000 pcs/h by 50 mm wire length (Crimp/Crimp) [1] |

Performance and geometry |

|

| Drive | Servo motors |

| Number of stations | up to 6 stations |

Controls |

|

| Software | WireStar |

| Display | 21″ Touchscreen |

Supplies and interfaces |

|

| Power supply | 3x (208-480 V), 50/60 Hz, 3.5 kVA |

| Compressed air | 6 bar |

| Interfaces | RS232 Ethernet |

Dimensions & Weight |

|

| Width x Depth x Height | 3350 x 1450 x 1800 mm [2] |

| Weight | 1050 kg [2] |

[1] Depending on the configuration of wire and terminal.

[2] Approximate indication for basic equipment.

Subject to errors and alterations.