Individual Molding Solutions

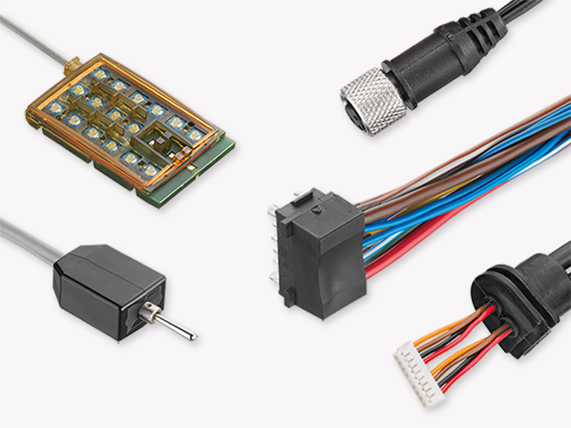

We offer innovative solutions for hotmelt molding. With this process, connectors, cable entries, and circuit boards can be protected.

To ensure connection systems can withstand extreme conditions such as heat, dust, or moisture, Schäfer offers cost-effective and efficient solutions with hotmelt molding technology. Using a low-pressure process, components are molded and sealed at the wire or terminal.

We are pleased to advise you and assist in configuring your solution based on machine, tool, and material.