Semi automatic processing of fiber optic cables

Solutions for Wire Processing

The Schäfer Group specializes in the development and manufacture of tooling as well as standard and special machines configured as bench-top machine, semi automatic machine and fully automatic machine especially for crimping, cutting and stripping in the wire processing industry. The company’s product range is complemented by quality control products as well as mold and die tooling.

Wire Processing Applications

Applicators for Wire Processing

Machines for Wire Processing

SpeedLine 22 ADVANCED

Fully automated cable production with wires ranging from 0.08 to 6 mm² cross-section at up to 4 stations

SealLine 240-3 ADVANCED

Sealing and crimping of three single wires or three-core cables in one machine cycle

Stripping and Twisting Machine ST730

Stripping of single wires and coaxial cables with small cross sections

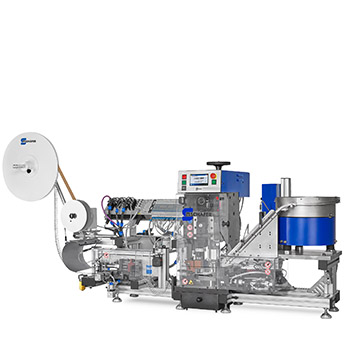

PlugLine 345-3 EXTENDED

Semiautomatic connecting of multi-core wires with plugs for production of power cables

SealLine 240-2 ADVANCED

Sealing and crimping of two single wires or two-core cables in one machine cycle

FerriteLine 240 ADVANCED

Bending of terminals, assembling with ferrite cores and crimping on two wires

SynchroLine INDIVIDUAL for Solar Applications

Fully automatic production of electric components for solar applications

TransLine 240 ADVANCED

Crimping and stripping of individual wires with extended functions for quality assurance

SpeedLine 33 INDIVIDUAL

Fully automated cable production with wires ranging from 0.08 to 8 mm² cross-section at up to 6 individual stations