Crimping of individual wires with various options

Crimping Machines

Schäfer offers innovative solutions for the production of high-performance crimp connections in terminal and wire processing. A range of machines is available for various application areas with a pressing force of up to 150 kN. Modernize your machinery and integrate the latest software solutions for operation and networking of machines in the spirit of a Smart Factory.

Crimping Presses for Typical Applications

TransLine 240 ADVANCED

Crimping and stripping of individual wires with extended functions for quality assurance

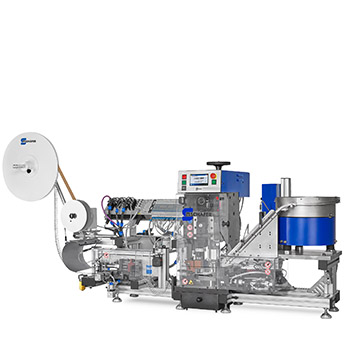

SealLine 240-2 ADVANCED

Sealing and crimping of two single wires or two-core cables in one machine cycle

SealLine 240-3 ADVANCED

Sealing and crimping of three single wires or three-core cables in one machine cycle

Crimping Presses for Special Applications

FerriteLine 240 ADVANCED

Bending of terminals, assembling with ferrite cores and crimping on two wires

Crimping Applicators for Cable Productions

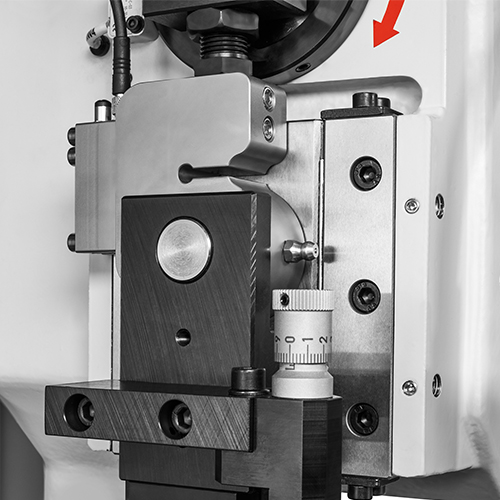

SolidCrimp ML-6

Mechanical crimping with side feed for small cross-sections and maximum precision in cable production

AirCrimp PL-6

Pneumatical applicator with side feed for small cross-sections and maximum precision in cable production

AirCrimp PL-6-WD

Pneumatical applicator with side feed for crimping individual terminals to wires with small cross sections

AirCrimp PL-16

Pneumatical applicator with side feed for crimping individual terminals to wires with bigger cross sections

AirCrimp PL-25

Pneumatical applicator with side feed for crimping individual terminals to wires with bigger cross sections

SolidCrimp MB-6

Mechanical applicator with back feed for crimping individual terminals to wires with small cross sections

SolidCrimp MB-6-SP

Mechanical applicator with back feed for crimping DVB connectors to wires with small cross sections

AirCrimp PB-6-WD

Pneumatical applicator with back feed for crimping individual terminals to wires with small cross sections

Quality Equipment for Wire Processing

Crimp Quality Sensor SDS100

Precise and direct recording of measured values for monitoring crimp quality

Individual Solutions for Cable Productions

Semi automatic processing of fiber optic cables

Production of insulation displacement connections

Production of insulation displacement connections on electric motor stators

Stripping of single wires and coaxial cables with small cross sections

Fully automatic production of fiber optic cables

Fully automatic production of cables for medicine applications

Crimping of individual wires with a modern safety concept

Crimping of individual wires with a modern safety concept

Semiautomatic connecting of multi-core wires with plugs for production of power cables

Fully automated cable production with wires ranging from 0.08 to 8 mm² cross-section at up to 6 individual stations

Designations at a glance

Formation of the name

- CrimpLine: Perfect for creating individual crimp connections on wires with small and large cross-sections.

- StripLine: Extended functions for cable preparation, such as cutting and stripping.

- TransLine: Additional processes with a transverse moving gripper, ideal for multi-core cables and special crimping operations.

- FerriteLine: High-quality cable production with ferrite cores, including feeding and separating the ferrite cores.

- SealLine: Specially designed for cable productions with seals, featuring unique preparation processes.

- PlugLine: Optimized for cable productions with plugs, including separating and feeding the contacts.

- ProLine: Programmable crimping machines for maximum flexibility, with adjustable servo drives and integrated recipe management.

Distinction of types

The additional abbreviations for distinguishing the types describe, e.g.:

- 240 = 2 t pressing force with a press stroke of 40 mm

- 640 = 6 t pressing force with a press stroke of 40 mm

- 1550 = 15 t pressing force with a press stroke of 50 mm

The differentiation into various versions means:

- BASIC: Machine without its own control system

- ADVANCED: Machine with programmable logic control system

- EXTENDED: Machine with fail-safe programmable logic control system

- INDIVIDUAL: Machine with customer-specific design